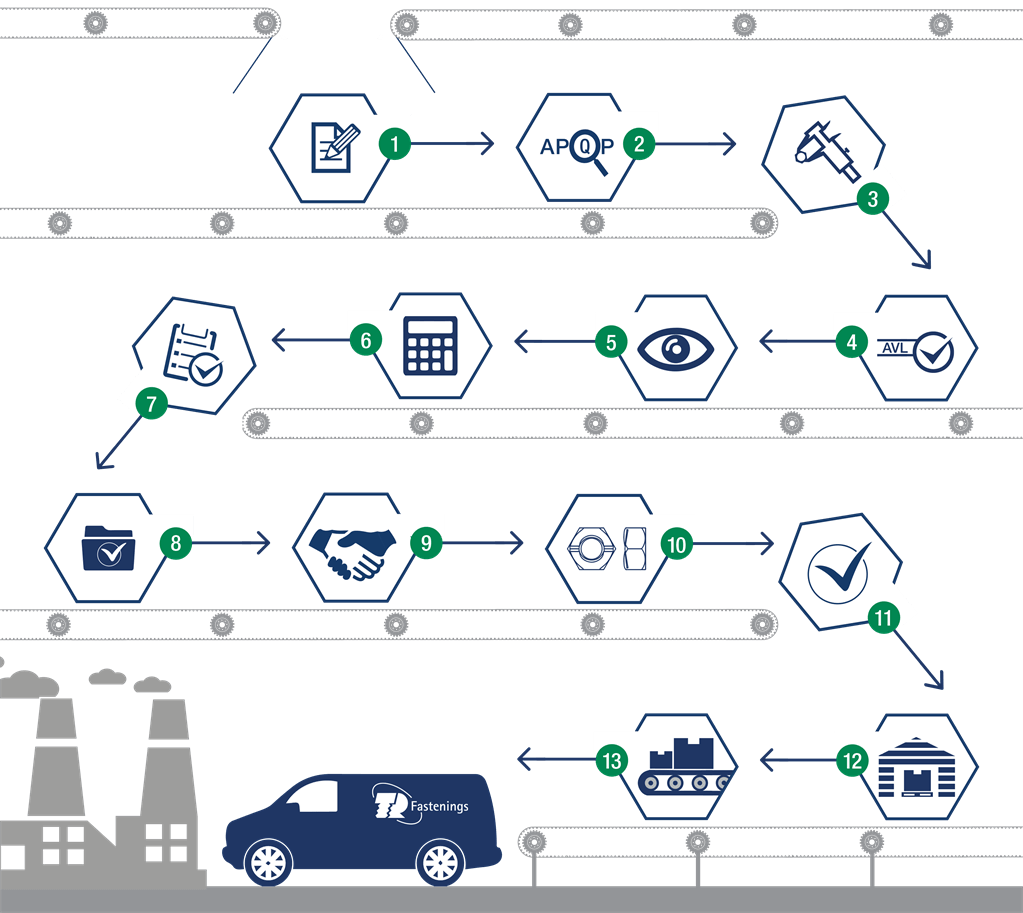

Advanced Product Quality Planning

To ensure all quality requirements are met for the parts we supply, TR adopts an APQP process for all automotive customers which can be utilised on request for any sector.

Request for quote received from customer

A request for quote can be received in a number of ways: through our external sales team, existing accounts can use their dedicated account manager or enquiries can come through our website. Enquiries are then qualified and we ensure we have the required documentation to enable us to proceed.

RFQ entered on to APQP portal

Whether new or 'carry over' parts, all automotive and designated enquiries are entered onto the APQP portal. This TR bespoke intranet portal is designed to set the following APQP tasks into a measureable timeline. Each task is monitored to ensure that our customers pre-production timescales are met.

Feasibility review

All drawings and standards are reviewed by TR Feasibility Engineers to ensure that the full extent of the customers requirements are understood. Once critical and safety critical characteristics are identified, the Engineers work closely with the New Product Introduction Team to ensure that the correct supplier is aligned with the requirements.

Source product from Approved Vendor List

The TR Automotive AVL is managed by a dedicated Commercial, Quality and Sourcing team. Suppliers are added to/removed from the AVL based on business needs or supplier performance. The AVL team is supported by Supplier Quality Managers in Europe and Asia. The SQM Team audits suppliers on an on-going schedule and develops suppliers based on improvements identified.

Review supplier quote

It is the responsibility of the Feasibility Engineers to compare the suppliers capability of manufacturing against the customers requirements, identifying any differences and ensuring that these are understood and approved.

Commercial review

It is the responsibility of the relevant TR division to complete a cost model to assess any additional costs pertaining to servicing the account e.g. stockholding, premises, labour costs and the movement of the product. This is then reviewed in line with turnover and working capital expectations and authorised accordingly. This enables us not only to remain competitive, but can also help in offering additional value to both parties through alternative logistical solutions.