Competencies

Complex cold formed multi-die products in both male and female forms.

Tool Design & Development

This is the most important part of the manufacturing process. Our experienced team of Engineers use the latest simulation software to develop the tooling and ensure that the design is capable.

Vendor Selection

TR PSEP works with a limited number of material suppliers to ensure that the raw material is of the highest quality and our subcontractors are all accredited to the TR PSEP & TR Fastenings Quality Management System (QMS).

Quality

TR PSEP strives to achieve excellence in everything it does, and this flows through our manufacturing sites and across all manufacturing disciplines and operational areas.Research & Development

Our goal is to solve tomorrow's challenges today.

Together with our experienced team of Engineers we are developing award winning designs such as the self-extruding EPW screw, winner of Fastener and Fixing magazine’s ‘Route to Fastener Innovation 2019; and we are committed to working with local universities to understand more about light weighting, electric vehicle (EV) & electric vehicle battery (EVB) developments, allowing us to develop cost effective solutions for your existing and applications of tomorrow.

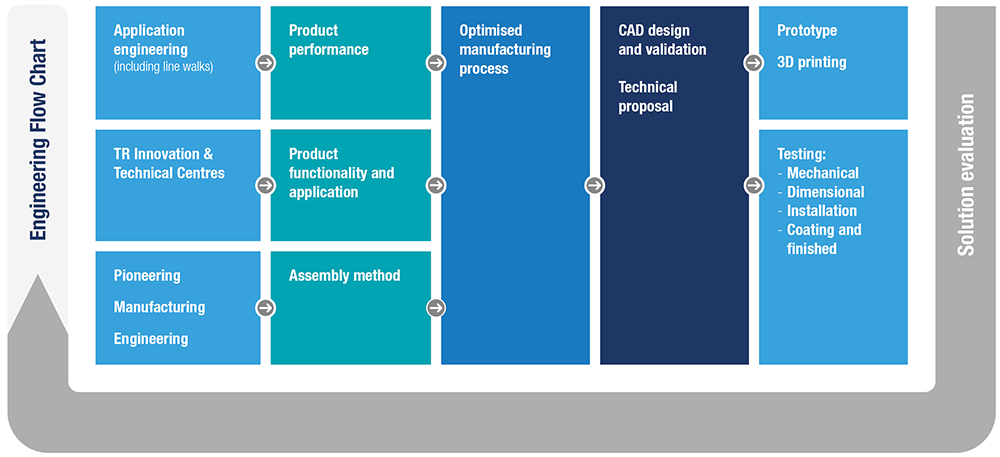

Application Engineering

TR recognises that the development of applications is a time-consuming process, which is why our team of fastening specialists are on hand to support and guide you in the development of new products.

Cold Forging

TR PSEP have a large range of heading machines from simple 2 die 2 blow to 6 die 6 blow machines for the manufacture of complex cold forgings, ensuring that customer designs can be manufactured in the most cost effective way.

Thread Rolling

Our rolling operations start at M3 diameter and cover both standard and licensed products to a maximum of M20.

SEMS (washer assembly) is also covered up to and including M12.

Secondary Operations

TR PSEP offers a wide range of secondary operations to complement our cold forging capabilities, these include pointing, drilling, tapping and CNC machining.

Heat Treatment

Continuous hardening and tempering is a process carried out in a controlled protective atmosphere by heating the parts to between 820˚c and 910˚c and quenching in oil. The temperature will be determined by the steel specification, either alloy steels or carbon.

- Fasteners M3 - M20 diameter and 200mm length

- Capacity of 150 tons per week

- Infrared camera monitoring and recording

Surface Treatment

TR PSEP is able to offer all relevant automotive finishes e.g. Cr3 zinc (clear, black and blue), Cr3 zinc nickel (clear, black and blue), zinc flake (silver and black), self lock coating & de-embrittlement.

Additional coatings along with thread locking, sealing, patching are available from our partner suppliers within the region.

Optical Sorting

TR PSEP have in house capability for optical sorting.

Logistics

TR PSEP has the flexibility to deliver directly to global OEMs utilising the Groups global distribution footprint.

Contact us - sales@tr-psep.com